A products lifecycle doesn't end, once it has left production. Extend your product management from design all the way to the shelf with operational history and device traceability.

It can also facilitate processes like customer complaints, ensuring seamless traceability even after the product has entered the market.

Highstage enables management of serial numbers, lots, or batches for manufactured and shipped devices. This allows for complete traceability both from the design phase ("where used") and the reverse process from the device itself ("how designed").

When integrated with a company’s ERP/MRP system, Highstage manages the technical aspects of device oversight, while the ERP handles financial and transactional elements such as invoicing. A solid integration improves overall efficiency and customer satisfaction.

Highstage facilitates collaboration with suppliers and manufacturers through several methods, such as synchronizing serial or batch numbers during or after production.

Another option is to provide self-service access to manufacturing documentation through a dedicated supplier portal.

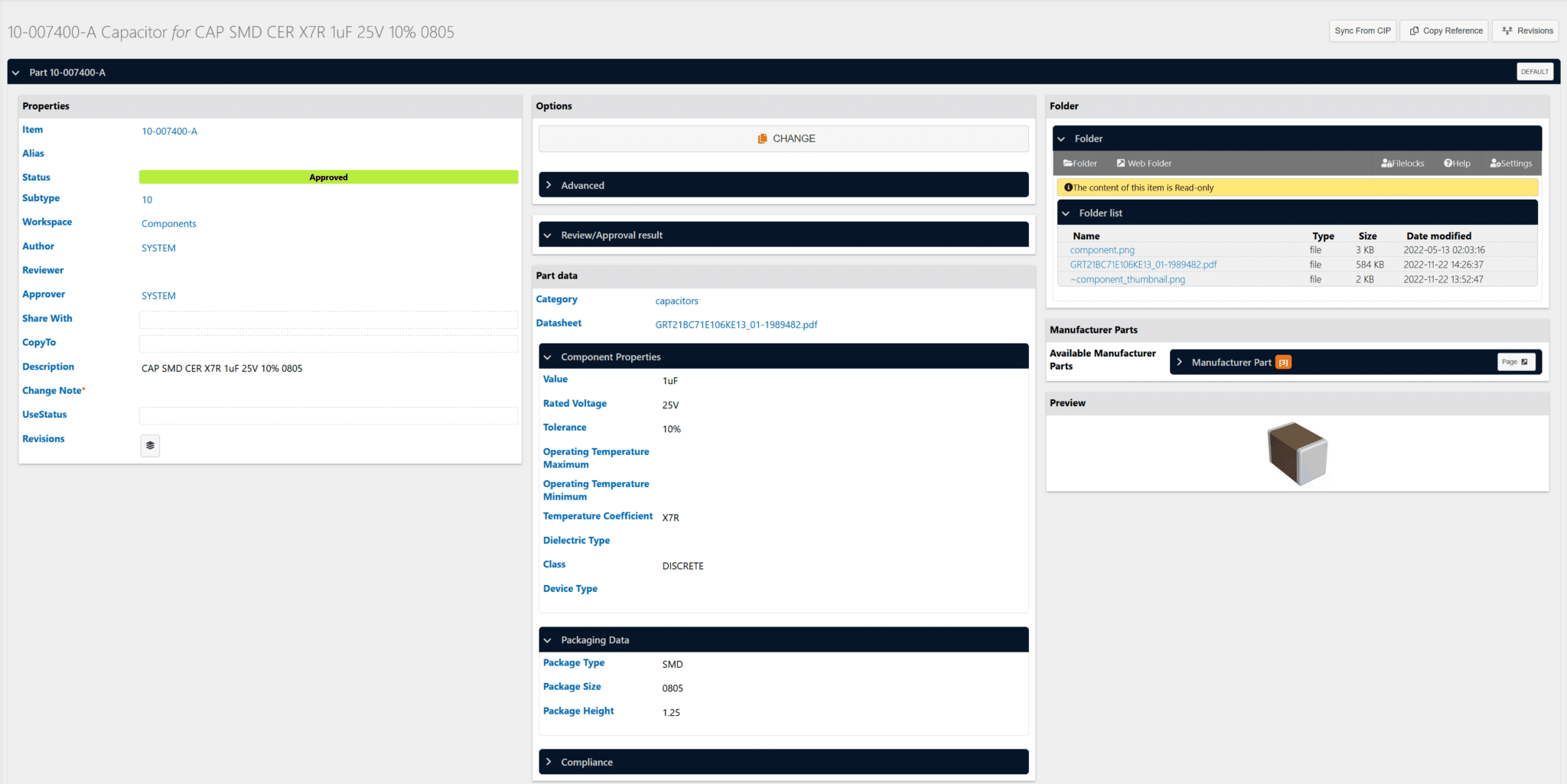

The Highstage Part Module allows for the design of configurable part assemblies, with options and rules for using alternatives.

This flexibility supports creating custom configurations for each manufacturing or procurement job, allowing for multiple variants based on one main part.

For instance, a manufacturing manager can order 100 units based on a specific configuration, and all data remains fully traceable.

In addition to internal configurations, some options can be made available directly to customers via a webshop. Highstage can power the backend, ensuring that only valid configurations are available for purchase, such as color choices or accessories.

Each part or sub-assembly can be assigned a machine-readable code, such as a barcode or QR code, containing serial numbers and part definitions with revisions.

This system can be used in assembly lines, allowing essential components to be scanned as they are added to the product, ensuring traceability and generating full manufacturing logs post-assembly.

For complex devices with multiple sub-components, Highstage helps track each sub-device’s location and status over time.

For example, if a serviceable part like a gear is replaced and overhauled, Highstage will log the histories of both the replaced and new components, providing a complete record.

Combined with QR codes, it becomes easy to track the configuration of all delivered devices at any moment.

Highstage is soon launching a comprehensive maintenance system that works with the Device Module.

This system will support condition-based maintenance planning, triggered by factors such as data, operational hours, or time periods.

Maintenance plans are generated for sets of devices, and completed services are logged within the system, offering a full-featured maintenance solution.